KELLER in the gas industry

01. December 2020

Gas meters of different designs are used worldwide to monitor the consumption of gas energy in commercial and industrial applications.

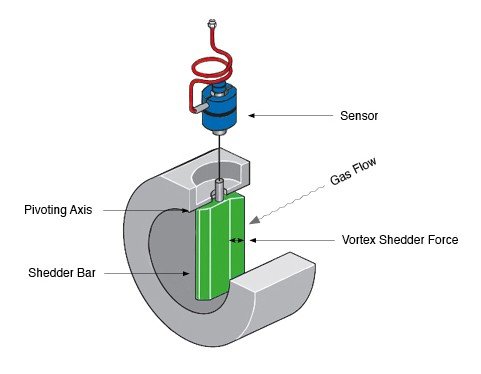

One example is the vortex flow meter:

This meter operates on the principle of vortex shedding. Using an integrated temperature sensor and a pressure sensor, the meter software can compensate for changes in pressure and temperature, enabling precise measurement of the mass flow for gas metering purposes.

Natural gas

Gas meters, or gas flow meters, measure the volume of natural gas or technical gases.

Since natural gas is compressible, the volume measured by the gas meter depends on the gas pressure and the temperature. In order to convert the volume into an actual energy value, another standard volume (or volume at standard pressure and temperature) must be added.

Turbine meters, ultrasonic flow meters and rotary displacement meters only measure the actual volume

According to Boyle's Law and Gay-Lussac's Law, together referred to as the ideal gas law, at a constant temperature but with a slight change in pressure, the actual volume and the volume at standard pressure and temperature can change drastically.

For a precise measurement of the energy value of the gas, all manufacturers of gas meters have to use a pressure sensor. This measures the actual pressure and converts it into a standard flow rate by means of pressure compensation (the flow rate is measured in Nm³).

A variety of technical standards for gas meters exist worldwide (EN 12405 --> EU, GBT 32201-2015 --> CN, ISO 9951-1993 --> international, OIML-R138-1 --> international, AGA 7 --> USA). These define the accuracy of the gas meters. However, there are no direct definitions for the accuracy of the pressure sensors.

Pressure sensors for the gas market must meet two common accuracy requirements:

Type 2: 0,2 % of rdg at a temperature of -20…60 °C from 20…100 % (5 bar, 10 bar, 20 bar).

Type 1: 0,2 % of rdg at a temperature of -20...60 °C from 50…100 % (5 bar, 10 bar, 20 bar).

The D-line from KELLER meets the requirements of Type 1.

For the high requirements of Type 2, KELLER Pressure offers two possible products:

pressure transducers with mathematical modelling (analog signals), or the digital X-line transmitters.

KELLER Pressure therefore offers a wide range of products that are used for gas metering applications, making it perfectly positioned to meet the various requirements.